Description

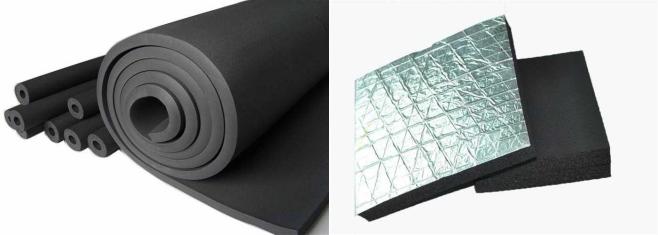

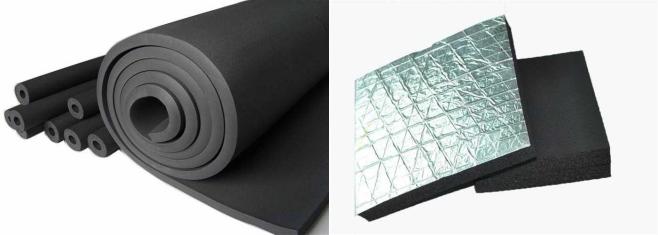

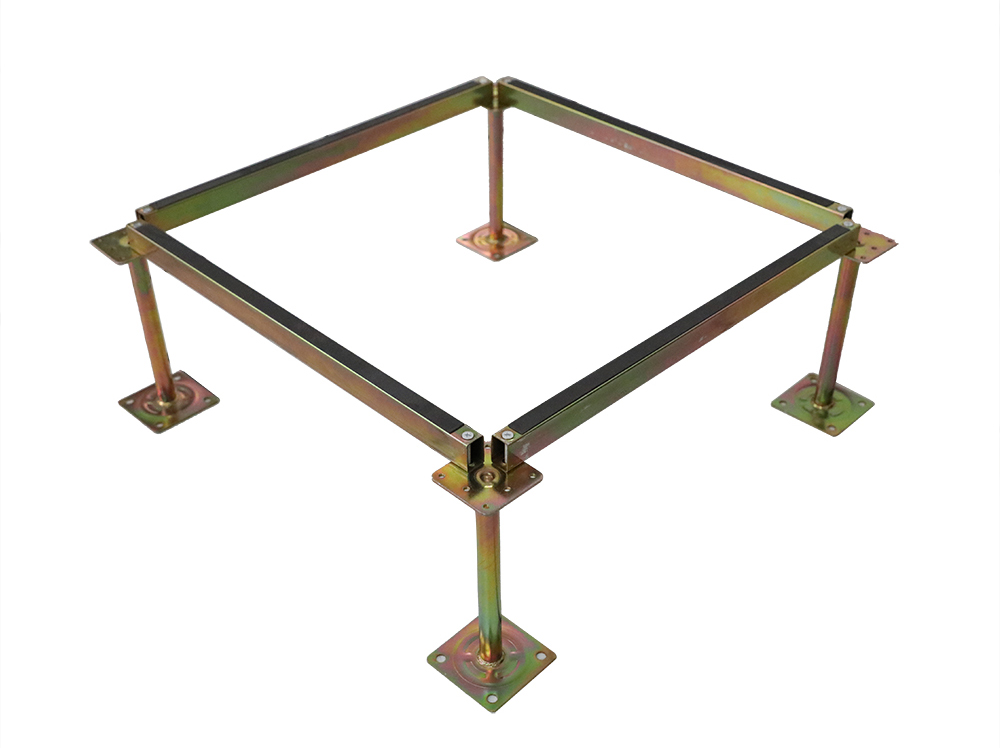

ClosedCell Insulation with Aluminum Foil is the environmental protection product, it is widely applied in architecture, textile, medicine, chemical industry, metallurgy, shipbuilding, etc. It is also widely used under raised floor system for Heat Preservation Function.

Characteristics

● Equipped with foam structure, small coefficient of the thermalconductivity

● Excellent adiabatic effect, which can save energyconsumption

● Equipped with air bubble structure and dense skin, which makes water vapor not easily through, bibulous rate islow

● High flexibility, installation isconvenient

● Appearance is elegant andclean

● Applicable temperature range can be from -40℃to 105℃, excellent fire resistant performance

● Unique flame retardant formula makes material has good fire retardanteffect.

Heat Conductivity

While average temperature is 0℃, the thermal conductivity for insulation is 0.034W/MK, it’s surface heat emission coefficient is still high. So in the same external conditions, compare with other thermal insulating materials, our insulation can achieve the same heat insulation effect with thinner thickness, which saves room under raised floor system.

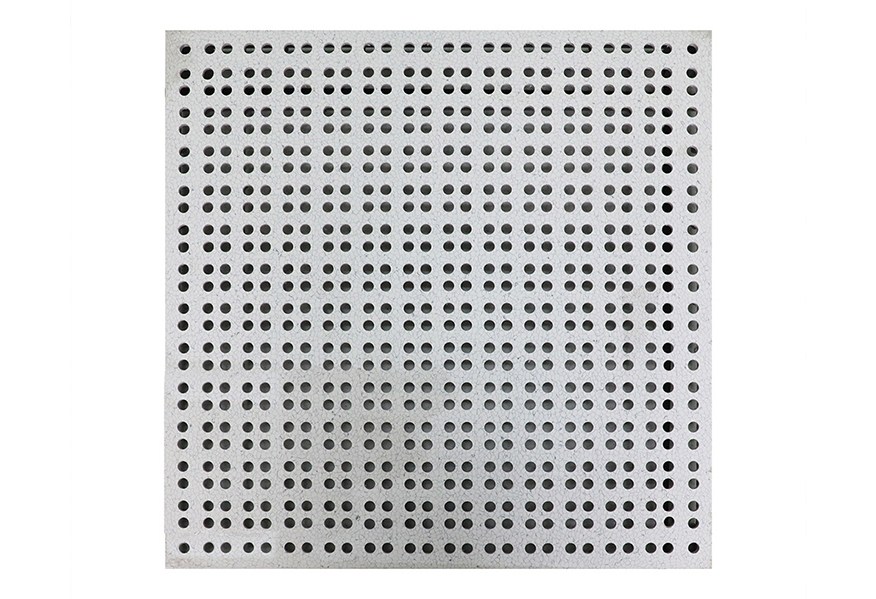

Closed Cell Structure

Outside air humidity is difficult to permeate in our material, this excellent resistance to water vapor permeability, allow that there is no need to add vapour barrier on the insulating layer. The damp obstruction factor U value is be equal or greater than 4500, this forms a defogging layer, which makes the whole system warm and dry.

High Flame Retardant Property

This material contains a lot of flame retardant minus smoke raw material, combustion smoke from the concentration is extremely low, insulation won’t be fusion. No fireball drops, and material has self- quenching properties.

According to GB8624-1997 “Building Material Combustion Performance of Grading Method”, this material is the B1 level product, which is flame retardant material to ensure safety and reliability.

Item | Performance NBR/RVC |

Density kg/m3 | 45-80 |

Equation of Thermal Vonductivity .W/(m.k) | 0.0337+0.0001375tm |

Applicable Temperature | Upper limit | 105℃ |

Lower limit | -40℃ |

Temperature Stability | <4% |

Ozonization Resistance | Good |

Water Absorption (28 Days of Immersion) | <4% |

Damp Obstruction Factor | ≥4500 |

Combustion Performance(B1Level) | A)Oxygen Index | ≥33 |

B)Average Burning Time.S

|

≤30 |

C)Average burning height.mm |

≤250 |

D)Smoke density rating(SDR) |

≤75 |

Download

Download

CopyRight © 2024 - Changzhou Huateng Access Floor Co., LTDAll rights reserved

CopyRight © 2024 - Changzhou Huateng Access Floor Co., LTDAll rights reserved